Best Practices for Incoming Inspections in Manufacturing and Service Industries

Incoming inspections play a pivotal role in ensuring quality and consistency in the manufacturing and service industries.

What is Incoming or Receiving Inspection?

In the manufacturing industry, businesses create Purchase Orders for Products or Services required from a 3rd Party, typically referred to as a Supplier or Vendor. Upon receipt of the product or service, reviewing what was received versus what was ordered is called Incoming Inspection.

This practice is crucial for quality assurance, ensuring that the received goods meet the set standards.

Levels of Incoming Inspection

Depending on the product or service requested many different levels of inspection exist.

1. Dock To Stock

All products or services from a Supplier are directly received and transferred into stock.

2. Sample Inspection

A predetermined quantity from the total received products or services is inspected. If compliant, the entire quantity is transferred into stock. It’s best to use the ANSI/ASQ Z1.4 standard, especially the Zero Acceptance Number Sampling Plans with a C=0 sampling plan. Simplifying further, use 3 Acceptable Quality Levels (AQL) – 0.5 for critical parts, 1.0 for major details or services, and 1.5 for minor features or services.

Additionally, samples must be taken randomly from the population and accurately represent the population of parts or services received.

3. 100% Inspection

As the name implies, all products or services received from a Supplier or Vendor are inspected, and if found in compliance, are received and transferred into stock.

4. Skip Lots

This incoming inspection method tracks each incoming receipt of a specific part number and will only perform an inspection on every x lot received. For example, it can be documented to perform an inspection on every 4th lot received.

So the 1st lot received is inspected, and then lots 2, 3 and 4 are received into stock within an inspection. The 5th lot received is then inspected. This process repeats itself.

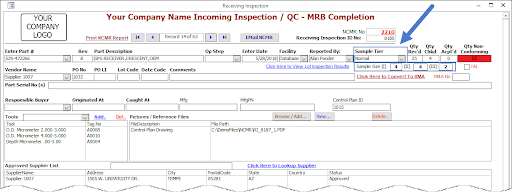

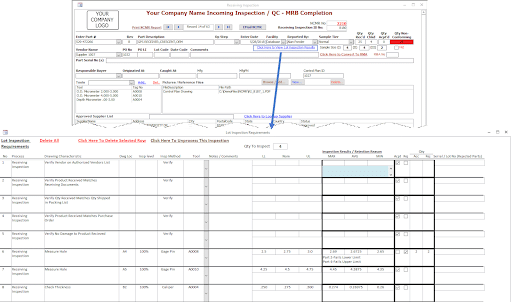

Database Providers Quality Management Software, specifically its Inspection and Nonconformance Material module, includes the inspection level as displayed below.

Defining Incoming Inspection

It is essential to identify what is to be inspected or verified.

Inspections can include documentation, purchase order requirements, and product or service attribute verification. If a problem is later identified, a review can occur of what was inspected to see if additional inspections should be added to the definition.

Control Plans, assigned to specific part numbers and revisions, can be instrumental in detailing what to inspect, the method, and criteria. They are easily copied and managed should the inspection requirements change over time.

Whether it be an incoming or receiving, or a work in process (WIP) or final inspection, defining what to inspect, the inspection method and criteria should be clearly defined.

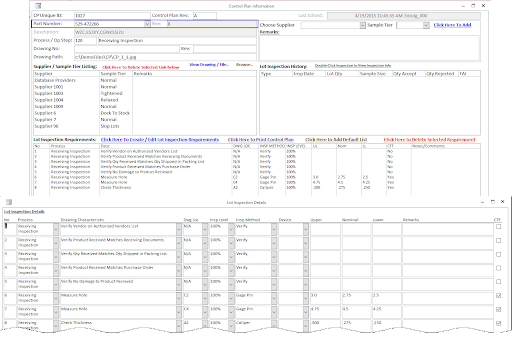

The Control Plan is based on a specific part number and has four sections of detail.

First, all of the Approved Suppliers are shown, each with an Inspection Level identified.

Secondly, there is a section to link to a drawing or other file.

Lastly, the Inspection Details which list all of the inspections that are required, each one.

An example of a control plan for a specific part number and revision is shown below.

When control plans are utilized, Database Providers Quality Management Software, creates the lot’s inspection record, based on the control plan, for each Incoming or Receiving Inspection.

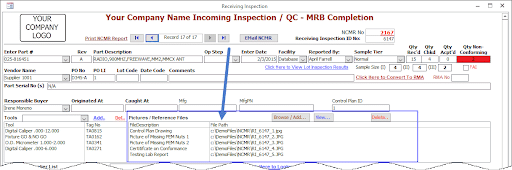

As the inspection is completed, the inspector completes the form. If any non-conformances are found, a single click creates a nonconformance record. An Example of a completed Incoming Receiving Inspection shown below.

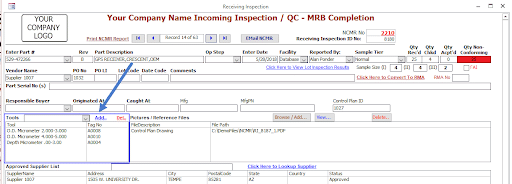

1. Capturing List Of Measuring Devices Used During Incoming Inspection

It is essential to identify what is to be inspected or verified. Inspections can include documentation, purchase order requirements, and product or service attribute verification. If a problem is later identified, a review can occur of what was inspected to see if additional inspections should be added to the definition.

2. Capture Incoming Inspection Personnel

Capturing who performed the inspection is an essential piece of information. Any nonconformances found after receiving the product into stock can be traced back to the inspectors.

Inspectors with more post-receipt rejections can be further trained or have testing performed to ensure their inspection capabilities. Cases of finding inspectors having poor vision have resulted in companies investing in prescription glasses.

Cases of inspectors that cannot read have resulted in reading classes. If there is an expectation of being able to read and see to perform tasks assigned to personnel, then the business should identify a process for validating this requirement.

3. Identification of Inspected Products and Services

If a business decides it is vital to perform an incoming inspection, then a process should be in place to indicate that products or services have been inspected from those that have yet to.

4. Linking Documentation to Inspection Records

Each Incoming Inspection includes documentation – Packing List, Certificate of Conformance, Testing Results, etc.

Where these documents are stored, and the names of files vary from business to business. Finding these documents can become a laborious task. If these documents can be linked to the incoming inspection record, they become easy to find, view and print out if necessary.

In addition, should a nonconformance be identified, pictures of the nonconformance can be added, red-lined drawings of the missing feature, etc.

An example of how this is used within an Incoming Inspection record is shown below.

To Conclude

Incoming inspections are integral to maintaining quality in the manufacturing and service sectors. By adhering to the best practices outlined above, businesses can ensure consistency, reduce errors, and uphold their reputation for excellence.

Explore further inspection techniques with our Quality Management System Software. Learn more about specialized tools with our Inspection & Nonconforming Material Software.

Ready to see these solutions in action? Book a demo by contacting us for personalized information tailored to your needs.