How to Select calibration management software?

Calibration Management Software is a key part of today’s business operations. It helps businesses manage and control their measurement devices and processes. This ensures accuracy, reliability, and compliance, which are crucial for any organization to maintain high standards and meet industry regulations.

A well-calibrated equipment is crucial for accurate and reliable measurements. The essence of calibration transcends across various sectors including manufacturing, aerospace, and healthcare, forming the foundation of quality and safety in operations.

Calibration management is an essential step towards precision, ensuring that every instrument and equipment performs with accuracy. However, manual calibration processes can be time-consuming and prone to errors. The modern solution to this challenge is the adoption of digital tools specifically designed to manage the calibration process seamlessly.

How to Select Calibration Management Software?

Selecting the right calibration management software is a critical decision that requires a thorough understanding of both the needs of your organization and the features offered by the software.

Here are some key factors to consider:

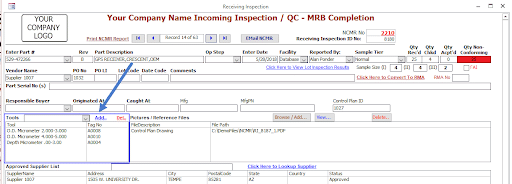

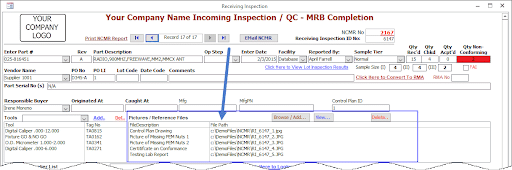

User-Friendly Interface

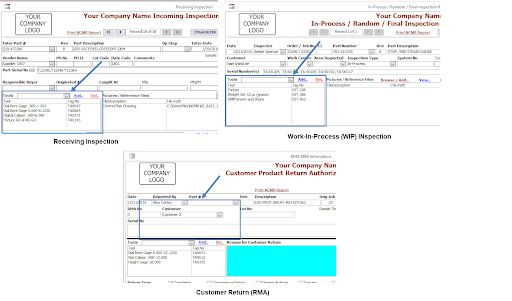

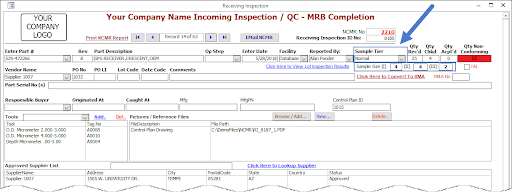

A user-friendly interface is essential for ensuring that the software is easy to use and navigate. This will facilitate quicker adoption among staff and ensure that the system is utilized to its fullest potential.

Customizability

Every organization has unique needs. A customizable software allows for the configuration of features to meet the specific requirements of your business.

Regulatory Compliance

Ensure that the software supports compliance with the relevant industry standards and regulations. It should have features that allow for easy reporting and audit trail capabilities.

Integration Capabilities

The ability to integrate with other systems and software used within your organization is crucial for ensuring a seamless flow of data and processes.

Support and Training

Look for providers that offer robust support and training services to ensure smooth implementation and ongoing usability of the software.

Cost Efficiency

While it’s an investment, ensure that the software provides value for money by evaluating its cost against the benefits and features it provides.

Vendor Reputation

Finally, consider the reputation and reliability of the vendor. Look for vendors with a proven track record of delivering quality products and exceptional customer service.

Importance of Calibration Management Software

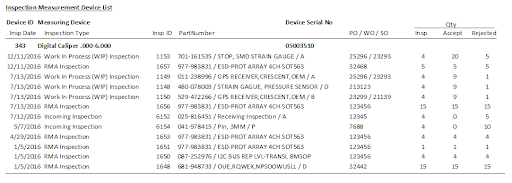

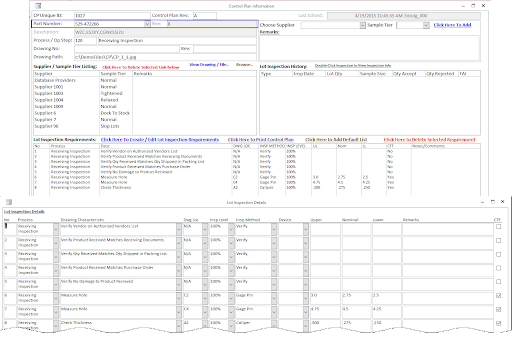

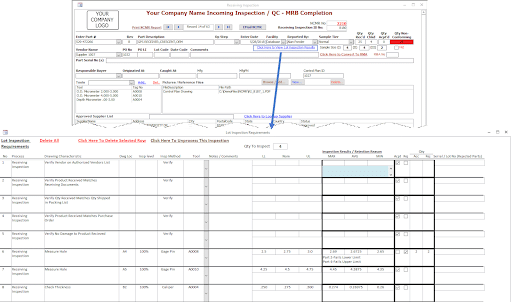

Calibration management software plays a crucial role in maintaining the integrity and quality of operations. It not only automates the process of scheduling and tracking calibrations but also ensures compliance with regulatory requirements, thus reducing the risk of non-compliance and the associated costs.

Moreover, ensuring that equipment is calibrated accurately and on time aids in reducing errors, saving time, and promoting a culture of continuous improvement within the organization. A well-maintained calibration record, facilitated by effective calibration management software, is a testament to an organization’s commitment to quality and precision.

To Conclude

Calibration management software is a key tool for modern operations. It simplifies the job of scheduling and tracking calibrations, saving both time and resources compared to traditional manual processes. By automating these tasks, the chance for human errors is reduced, ensuring equipment is calibrated accurately every time. This software also helps organizations stick to industry standards and rules by keeping precise calibration records and making reporting easy.

Looking for a Calibration Management Software? Check out our offers here.